When you discover a container of sustenance or even a jug of oil or universally handy oil, would you significantly try to go close it? This is the thing that that shows how noteworthy is the part of a name around the container. The estimation of the packaged thing is really decided with the naming that is done over it.

How would we mark a container? In prior times, the jugs used to be named and fixed by specialists who are all around prepared in naming. This clarifies the entire procedure of making the name, cutting it; use of paste and the way toward staying the mark around the jug were altogether done physically. As we as a whole know, manual work is constantly inclined to mistakes and the yield level will dependably vary. Thusly the need of developing a machine like round bottle labeling machine which is completely programmed or self-loader in usefulness came up.

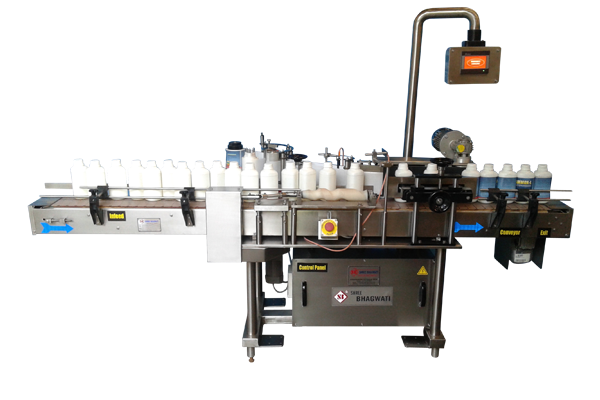

Technical Specification

| Model | BSL-120B |

| Label Height | 8 mm to 90 / 120 / 150 mm Standard* |

| Label Length | 12 mm Minimum |

| Label Roll Dia | 400 mm |

| Core Dia | 75 / 76 mm |

| Gap Between two Labels | appx. 3 mm |

| Product Diameter | 15 mm to 90 mm* |

| Electrical | 220 VAC Single Phase Power Supply (50/60 Hz) |

| Power | 1.5 Amp. |

| Capacity | 0.75 Kw |

| Speed | Up to 150 Labels per minute depending on Product and Label Size |

| Conveyor height | 830-875 mm* |

| Overall dimension | 1950 mm(L) X 1020 mm(W) X 1400 mm (H) |

| With T.G. Cabinet | 1950 mm(L) X 1020 mm(W) X 1600 mm (H) |

| Machine Directio n of Movement | Left to Right from operator side |